Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_mobile.php on line 142

Let your anti-rotation tab breathe a little.

The ins and outs of this quirky clutch feature

The ins and outs of this quirky clutch feature

General Purpose clutches are used on a variety of applications, but one thing that they have in common is that they are shaft mounted. They are commonly mounted directly on the engine shaft. Typical applications include construction equipment, floor grinders, grain augers, outdoor power equipment, hose reels, ag equipment, pump jacks, mobile compressors, stump cutters, shallow water outboards, and more.

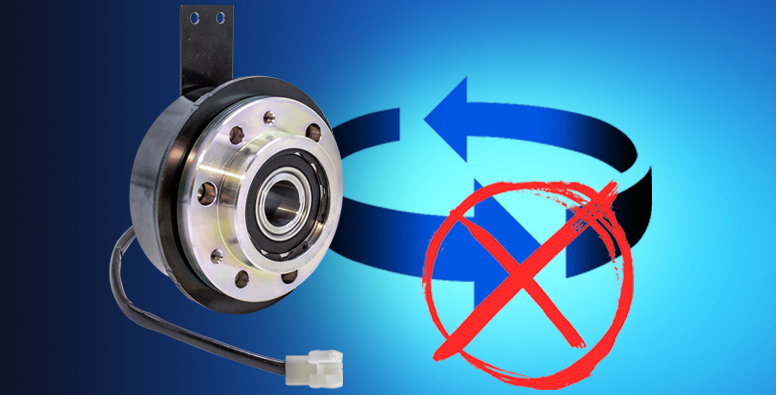

When looking at a general purpose electromagnetic clutch, there is a tab that protrudes from the coil body or coil backing. What is it? It is an anti-rotation tab. Ok, so what does it do? Well, when the electromagnetic clutch is mounted on the rotating shaft, something needs to keep the coil from rotating so that the wires do not pull out of the coil body. The anti-rotation tab is the feature that prevents your wires from ripping out due to the coil wanting to rotate on its own. But why does the coil want to rotate? The coil body rests on top of ball bearings. The bearings support the load. Bearings inherently reduce friction, but there still exists some level of bearing drag. That bearing drag will try to rotate the coil.

One of the most important things about the anti-rotation tab is that it should NOT be fastened down tightly. Check your clutch's installation manual and you will find that there should be some axial and radial clearance when loosely capturing that tab. If you tighten down a bolt to hold that tab steady, there is a good chance that you will induce some unwanted loads on the bearings and you may fail your clutch rather quickly. Remember to locate/hold that tab loosely. The amount of bearing drag is usually minimal, and it doesn't take much to keep the coil body from spinning.

For high vibration applications like stump cutters, equipment builders often use some type of rubber block or collar to locate the anti-rotation tab. This is because a metal pin or collar will make repeated contact with the metal tab, and it will cause both wear and noise. Since every application is unique, it is best to follow the OEM's recommendation since it is likely tested and approved for that level of machine vibration.

Ogura's GT and MA series of General Purpose clutches range in torque from around 110 lb-ft to 400 lb-ft for engines ranging from 5 HP to 40 HP. Bore sizes for most models correlate to popular engine shaft sizes of 1" to 1.7/16" but custom designs can be made for the right quantity. Most mobile application clutches have 12V coils but other voltages such as 24V can be available for certain sizes and quantities. Soft start controllers are available for these clutches.

Benefits of using an Ogura PTO clutch brake:

- Long life

- Safety

- Fuel and energy savings

- Fuel and energy savings

- Remote actuation option

- Many years of proven success

- For use with operator presence controls

- Available with a soft start controller

- Custom designs available based on minimum order quantities

- Reduced engine load on cold weather starts

- Increased operational life of driven equipment

- Simple installation