Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_mobile.php on line 142

How do I remove a pump clutch that is stuck on the tapered shaft?

We mount clutches on pumps and compressors to control on/offs, extend equipment life, save HP and fuel, to assist in cold weather starts, and for operator convenience. These are often underhood applications on tow trucks, service vans, ambulances, snow plows, construction equipment, and utility trucks.

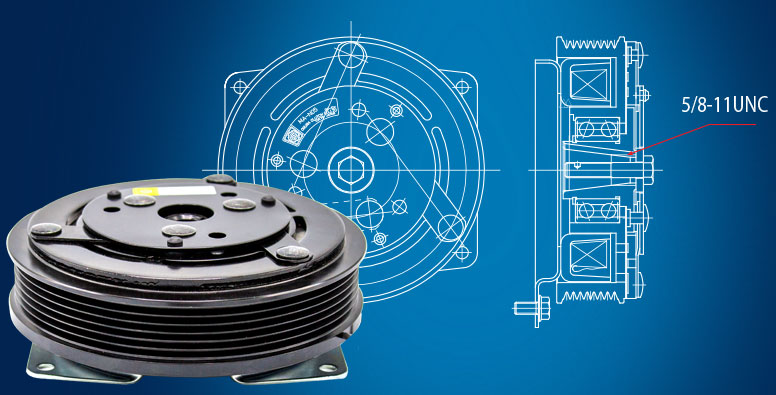

A common approach is to mount the clutch on the pump or compressor's tapered shaft. The clutch's field coil gets bolted directly onto the pump body and then the clutch's rotor gets centered onto the tapered shaft. The rotor is held on the shaft with an end bolt. It is an easy installation. If the clutch needs to be removed, it sometimes can be difficult to simply slide it back off. Thanks to Ogura's clutch design, there is an easy solution.

The rotor has a straight 5/8-11UNC thread. The only purpose is to help in removing the rotor from the shaft. After removing the end bolt from the shaft, simply insert a new bolt into that larger thread and the force should pop the rotor right off of the shaft.

Benefits of using an Ogura mobile and general purpose clutches:

- Long life

- Safety and convenience with remote starting

- Fuel and energy savings

- Built for outdoor operation

- Many years of proven success

- Custom designs available based on minimum order quantities

- Reduced engine load on cold weather starts

- Increased operational life of driven equipment

- Simple installation