Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_mobile.php on line 142

Which heavy duty electromagnetic clutches are designed to be driven by driveshafts?

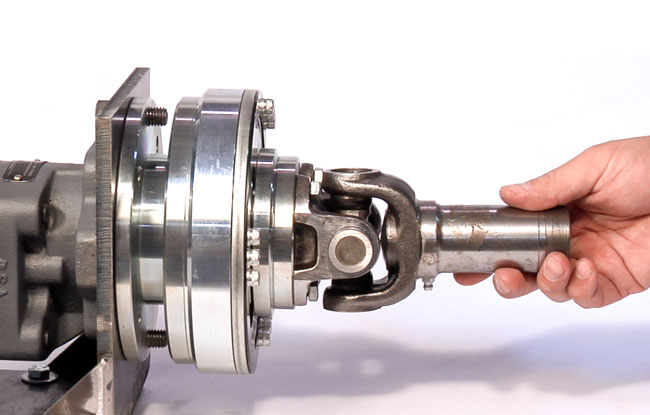

MMC universal hubs offer ease of installation in direct drive configurations. No special alignment is necessary.

Electromagnetic clutches with a torque rating of 200 lbft and higher torque are commonly used in direct drive applications. Furthermore, many of these applications utilize a driveshaft to power a large hydraulic pump, large compressor, pump jack, or other device. Ogura MMC clutches make installation easy, and extensive alignment is not necessary.

As torque transmission levels increase, many designers avoid using a belt driven or geared powertrain. Instead they use universal driveshafts for an inline drive. For applications assisted by a clutch for controlled engagements and disengagements, the driveshaft coupling can bolt directly to the clutch hub. The MMC series clutches have a standard bolt pattern to match common coupling designs. The MMC series clutches also remove the need to near-perfect angular alignment. For universal joint input, connect the universal joint companion flange to the four holes in the clutch face (or other direct inline coupling). Shaft misalignment must be less than 3 degree angularly with a shaft concentricity runout of no more than 3 thousandths (0.003") of an inch. These clutches are made to withstand heavy shock loads. They are what we consider heavy duty. Some of these applications can have high inertial loads, so we ask you to confer with Ogura before specifying a clutch because the recommended engagement speed may be much lower than the allowed operating speed. Ogura MMC clutches range in torque from 200 to 1,500 lbft and are made to operate in either direction. A variety of bore sizes and are available. Some of the smaller units come with a pulley option as well. Most mobile application clutches have 12V or 24V coils, but other voltages can be available for certain sizes and quantities. Soft start controllers are available for these clutches.Benefits you will see when using an Ogura electromagnetic clutch:

- Reduced engine load during cold weather starts

- Increased operational life of pumps and other driven equipment

- Fuel and energy savings

- Safety and convenience (remote starting)