Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_pto.php on line 142

Why do blades determine clutch life?

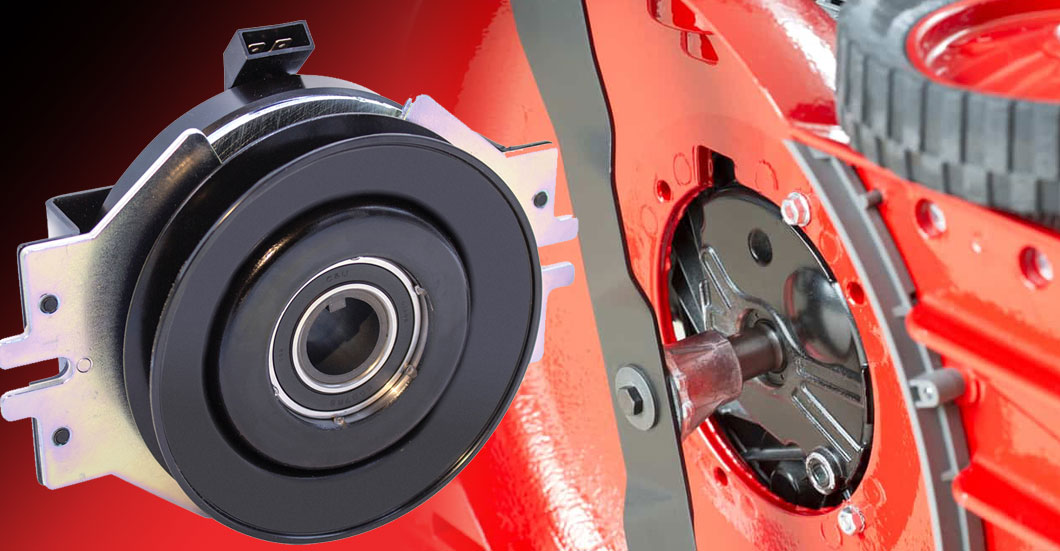

Sometimes it is interesting to find that some machine detail that seemed so trivial, has very deep importance. For example, what do the mower blades have to do with the life of a PTO clutch/brake? Surprisingly, a lot.

When a mower manufacturer designs and builds a mower, there is much thought and testing put into it. PTO clutches with safety brakes are critical components but they are also wear-components. When they engage at some speed, they wear a little bit each time. This is because they absorb some energy during every on/off cycle. That energy is based on two specific criteria: inertia and speed.

The inertia that we are concerned with is mainly based on those rotating blades. Afterall, the purpose of the PTO clutch brake is to start/stop those blades. Thick, long blades will have much more inertia than thin, short blades. So, by using longer, thicker, heavier blades, the cycle energy goes up and the wear increases as well. Think twice before trying to modify blades to get a different cut. Those were designed like that for a reason.

The best practice to limit wear on your PTO clutch brake is to slow down when engaging. In addition to inertia, energy is based on speed squared, so when you reduce the speed of the PTO shaft by 40%, you reduce the clutch and brake wear by about 64%.

Benefits of using Ogura PTO clutch brakes:

- Quality

- Safety

- Reliability

- Uptime

- Long life

- More time mowing