Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_pto.php on line 142

Why might integral connectors improve your machine?

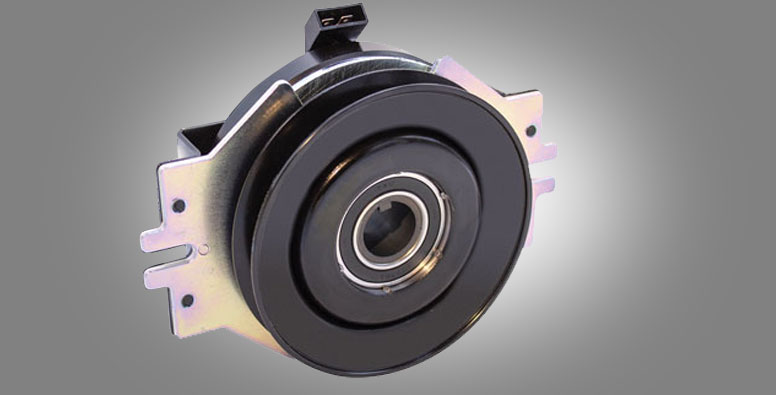

When downtime gives you nightmares, you need system designs that are robust and reliable. When it comes to PTO clutch brakes, the integral connector is a very convenient feature. These are used in various applications, but most commonly in consumer and commercial mowers, ag equipment, augers, mobile wood processing equipment, and more.

With traditional designs, the leadwire extends from the coil body. If a belt is thrown or debris interferes with the wire, it could rip completely out of the coil body and leave your machine sitting idle until a replacement clutch is found. Sometimes thrown belts and debris and just unavoidable. One reliable solution is to construct a clutch with an integral connector. This connector is firmly staked into the coil body. A jumper cable typically connects to the integral connector and the power source / battery. If the jumper cable gets damaged, the clutch remains unharmed and a simple fix is made to replace the jumper cable and get the equipment back in operation again. Either way, special consideration should be made to tuck loose wires out of harm's way to maximize machine uptime.

Ogura GT series PTO clutch-brakes are in made in a variety of configurations and typically mount on gas and diesel engines rated up to 40 HP. Bore sizes match the typical engine shaft sizes. Pulley sizes can vary based on machine requirements. Some have hub outputs to mount your own pulley, sprocket or coupling half. Clutch torque is rated up to 400 lb-ft on the larger units. These clutches typically operate on 12 or 24VDC.

Benefits of using an Ogura PTO clutch brake:

- Long life

- Safety

- Built for outdoor operation

- Many years of proven success

- For use with operator presence controls

- Available with a soft start controller

- Custom designs available based on minimum order quantities