Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_pto.php on line 142

What is a Flip-Set brake plate?

PTO clutch brakes are service items because they engage while rotating. These dynamic engagements cause the components to absorb energy, and that results in wear. Luckily for Ogura clutch users, when wear reaches a critical point, they can be adjusted and put back into use for even longer life. These PTO clutch brakes are predominantly used on higher end residential lawn tractors and commercial mowers but are also used on other outdoor equipment including blowers, forestry, construction, and ag equipment.

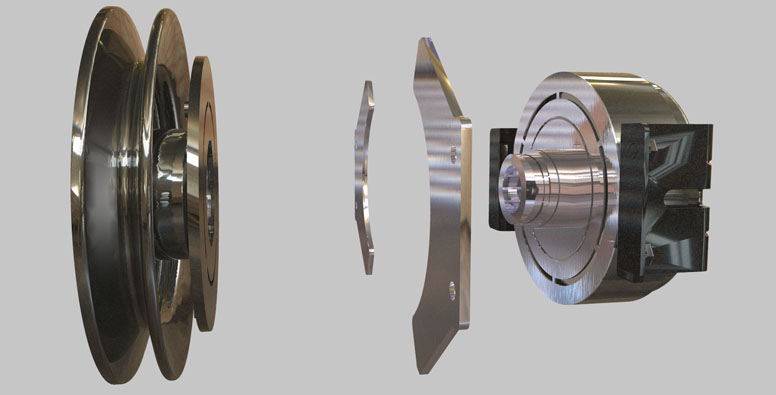

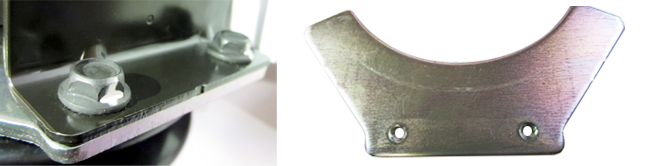

Adjustable-for-wear (Flip-SetTM) brake plates are used on the latest generation Ogura PTO clutch brake designs ranging from 110 lb-ft to 200 lb-ft torque. These are both a cost savings and down time savings for machine operators. Since the clutch has the ability to be adjusted while it is installed, the operator can make adjustments and quickly get back to work.

When the clutch air gap becomes too large because of wear, the clutch stops pulling-in (engaging). If that is the case, simply remove some small bolts and flip the brake pad to reduce the air gap. There are no measurements or fine tuning. It is an easy fix and sure beats sitting out in the heat wondering when you'll get a spare part ready.

Ogura GT series PTO clutch-brakes are in made in a variety of configurations and typically mount on gas and diesel engines rated up to 40 HP. Bore sizes match the typical engine shaft sizes. Pulley sizes can vary based on machine requirements. Some have hub outputs to mount your own pulley, sprocket or coupling half. Clutch torque is rated up to 400 lb-ft on the larger units. These clutches typically operate on 12 or 24VDC.

Benefits of using an Ogura PTO clutch brake:

- Long life

- Safety

- Built for outdoor operation

- Many years of proven success

- For use with operator presence controls

- Available with a soft start controller

- Custom designs available based on minimum order quantities