Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_pto.php on line 142

What special PTO clutch considerations are made for diesel engines?

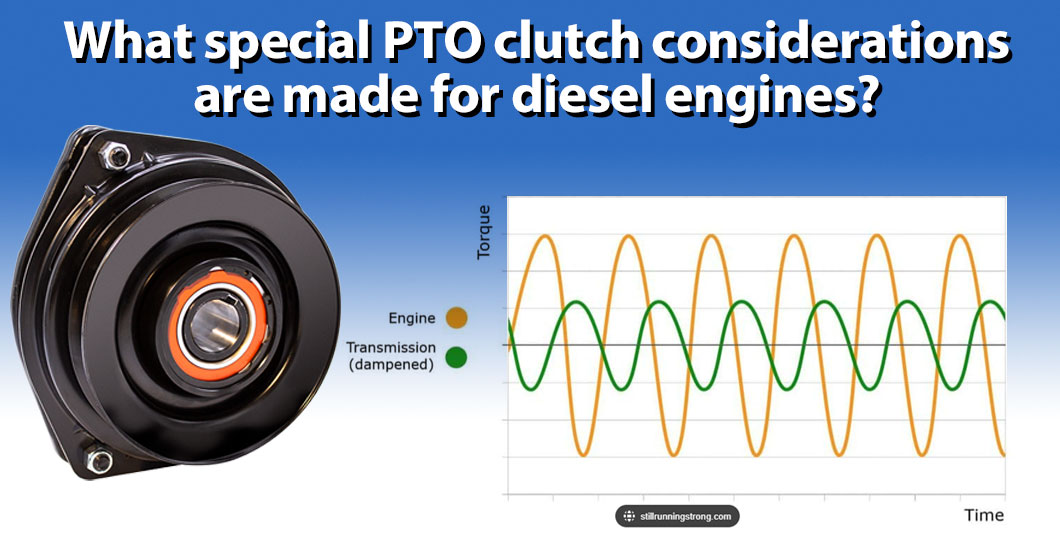

Engines cause vibration. Diesel engines are notorious for the worst vibration levels. They are rough on components, especially engine mounted clutches. These are used in various applications including commercial mowers, stump grinders, ag equipment, augers, mobile wood processing, off highway equipment, and more.

Vibrations tend to shake systems apart. Occasionally welds break, bearings fail, bolts come loose. That is why it is important to take special precautions and specify proper components. For Ogura's General Purpose and GT series PTO clutch brakes, it is common for clutches mounted on diesel engines to have strongly riveted backplates in lieu of welds. For some applications, reinforced leaf springs are utilized. Also, often times, different bearings are used to help prevent dreaded false brinelling induced failures due to vibrations while idling. Lastly, adequate locking compounds should be used with proper graded bolts and tightening torque to keep the assembly from loosening up and pulling apart.

Ogura GT series PTO clutch-brakes are in made in a variety of configurations and typically mount on gas and diesel engines rated up to 40 HP. Bore sizes match the typical engine shaft sizes. Pulley sizes can vary based on machine requirements. Some have hub outputs to mount your own pulley, sprocket or coupling half. Clutch torque is rated up to 400 lb-ft on the larger units. These clutches typically operate on 12 or 24VDC.

Benefits of using an Ogura PTO clutch brake

- Long life

- Safety

- Built for outdoor operation

- Many years of proven success

- For use with operator presence controls

- Available with a soft start controller

- Custom designs available based on minimum quantities