Notice: Undefined index: cid in /home/ogurasas/public_html/featured_product_holding.php on line 142

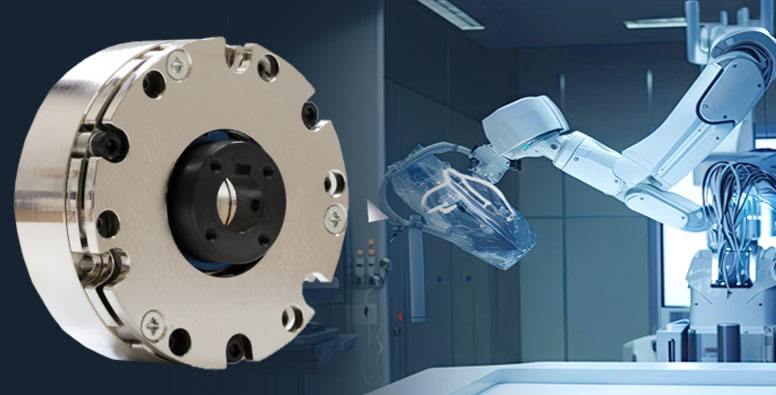

World's leading zero-backlash, low noise brakes for medical and robotics industries

Medical Equipment and Robotics Brakes

| Motor Frame | Size 40 | Size 60 | Size 80 |

| Model | MCNB-3Z | MCNB-15Z | MCNB-40Z |

| Brake OD | 35 mm | 52 mm | 68 mm |

| Voltage | 24 VDC | 24 VDC | 24 VDC |

| Static Torque (min) | 0.38 Nm | 1.52 Nm | 3.80 Nm |

| Allowable E-stops | 100 | 100 | 100 |

| Noise Level (max) | 60 dB | 60 dB | 60 dB |

Ogura’s new MCNB-Z series Spring Applied Brakes are changing the way robotics and medical equipment designers look at power-off holding brakes. These are typically used for both safety and precision motion control. For many years, permanent magnet type brakes were the only reliable solution. This is no longer the case, thanks to this new breakthrough design.

The product is spring applied type and truly zero backlash, which is unique. This means that loads can be held precisely when power is removed, improving the quality of the machinery and process. Traditional designs held zero backlash in the axial direction by fixing the hub to the friction disc, but this design also incorporates zero backlash in the rotational direction by removing play between the armature to the collar. This is important to note.

The applications involved are often noise sensitive, so the innovative design enables quiet actuation at 60dB or less.

The friction material is not bonded to the friction disc as typically seen. It is bonded to the armature and cover plate. This results in very low inertia of the hub and friction disc, which is very desirable in high cycling and high-speed applications.

The product is compact with super-thin profile and light weight. This provides benefits to robotic arm and motion control designers desiring smaller footprints, quicker system response times, lower system weight and cost.

Spring applied brake technology allows for lower power consumption as overexcitation releases the brake quickly, and pulse width modulation after the brake is released allows for 50% or more power savings. Reduced power then results in lower heat, extended overall component and system life. This ultimately allows improved warranties, reduced maintenance, and superior performance. They also offer distinct advantages in wide temperature range applications.

Lastly, they are easier to install since they are one piece construction as opposed to two-piece permanent magnet type construction.

Three standard sizes are available with a torque range of 0.38Nm to 3.80Nm. Custom sizes can be evaluated upon request.

Benefits of Ogura MCNB-Z brakes:

- Spring applied type as opposed to permanent magnet type

- Zero backlash

- Quiet to 60dB or less

- Super thin profile

- Low power consumption

- Low inertia rotating components

- Light weight

- Less expensive than permanent magnet types