Industrial Products by Type

Products Filtered by

Electromagnetic Clutches

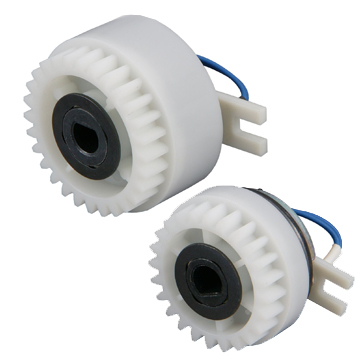

Small clutches for use in copy machines, printers, and other peripheral devices. This one-piece assembly features a custom-molded gear or timing pulley designed to your specifications. Most clutches use a permanent magnet to disengage the armature when it is not in use. All clutches are bi-directional. A three pronged dog bone output is also available.

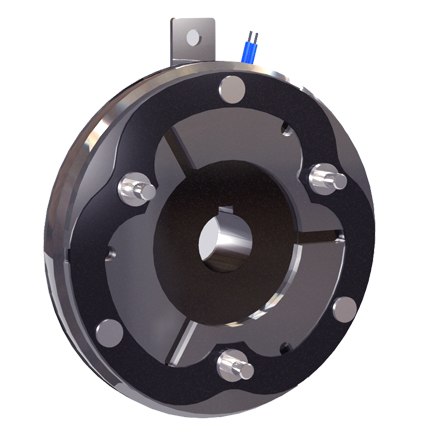

Heavy duty clutches best suited for marine and mobile applications. Bi-directional spring resists engine vibration and shock. Output can be modified to meet your requirement, or clutch can be purchased with armature only to bolt into your hub.

Clutch designed for general industrial use. Clutches are designed with zero backlash armatures and a double ball bearing field support to provide longer life and better performance versus bushing style units.

Clutch designed for general industrial use. Compact design with a thin overall profile. Zero backlash armatures can be built into custom hubs. Clutches are available with bearing supported field or a (no bearing) flange field. For replacements only. Not for new applications.

Clutch designed for general industrial applications. Units come standard with zero backlash armature. Units are normally produced in a high torque version but a lower torque is also available which reduces the overall length of the clutch by 15%. Options for this unit include an automatic air gap that adjusts as the clutch wears, a quiet armature option that reduces clutch engagement noise for applications in hospitals or offices and a 1 piece design option that simplifies mounting.

Clutch designed for general industrial use. Suitable for high speed and high cycle applications. Clutch has automatic wear adjustment mechanism which maintains proper airgap over life of the clutch to maintain a consistent engagement time.