Press Releases

Ogura's New Power-Off, Permanent Magnet Clutch

08-21-2024

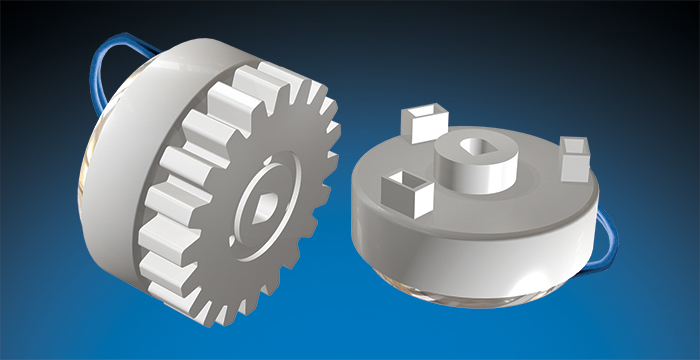

Model MPNC-3.5: A power saving, power-off electromagnetic clutch, which releases when electrical power is applied.

This one-of-a-kind design is an ideal power saving solution. This brand-new product is a normally engaged, power-off clutch intended for low power consumption, small envelope size, light weight, and high torque, while being extremely cost effective.

MPNC-3.5 is electromagnetic type, which means that it actuates when electrical power is applied. It disengages when 24 VDC is provided to the clutch coil. The magnetic flux of the powered coil cancels out the opposing magnetic flux of the internal permanent magnets. This allows for disconnection of the motor drive as required. Reasons to disengage a motor drive can include manual operation for service, repair, or for safety.

| CLUTCH | >MPNC-3.5 |

|---|---|

| Length | 19.5mm |

| Brake OD | 31.5 mm |

| Voltage | 24 VDC |

| Static Torque (min) | 0.44 Nm |

| Power Consumption | 2.4 W |

| Drag torque (max) | 0.03 Nm |

| Life (min) | 3M cycles |

| Weight | 30 g |

| RPM (max) | 500 |

| Power-on duty (max) | 10% |

The clutch delivers an impressive 0.44 NM minimum torque for its very small size and weight. It is intended as a reliable solution for many millions of cycles.

Ogura historically, and currently, manufactures a power-on clutch of this nature and provides millions of units annually to equipment OEM'S. This engineering advancement opens the door to many new markets looking for a "power-off" version to offer lower power consumption, smaller footprint, lighter weight, and high torque. While the power-on micro clutches are primarily used in paper handling applications such as printers, copiers, sorting, and ATM machines, the applications for the power-off variety expand much further. In addition to traditional applications, ideal applications include mobile robotics, medical devices, game systems, robotics and exoskeletons, 3D printing, sorting, drone systems, and much more.

The product can also be used as a power-off brake when the output is locked to a rigid frame. The output of clutch can be a universal type, dog bone style, for easy design compatibility, or it can be a custom extruded gear to match a customer's specific needs. The basic assembly stays the same.

The clutches are one-piece construction devices. They are easy to assemble, and airgaps are set at the factory. They do not require tight tolerancing like a typical industrial clutch. With lower power requirements (2.4W) they also run cool and dissipate heat effectively.

Ogura has been producing clutches and brakes since 1938. Over that time, we have developed over 5,000 different models of clutches and brakes. Although Ogura primarily produces electromagnetic clutches and brakes, we also produce magnetic particle, mechanical, pneumatic, hydraulic and a variety of specialty products. Ogura is the world's largest manufacturer of electromagnetic clutches and brakes. Current manufacturing capacity is over 30 million units per year. To provide localized support, we have manufacturing plants spread throughout the world in Asia, The Americas, and Europe. All manufacturing facilities are ISO recognized and conform to the ISO 9001:2015, ISO 14001:2015, and IATF 16949:2016.